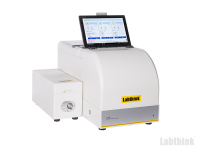

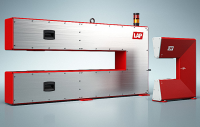

Labthink Vietnam, C230M, C230M Labthink, Hệ thống kiểm tra tốc độ truyền khí C230M, Đại lý chính hãng Labthink Vietnam

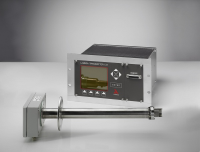

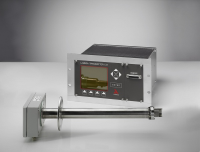

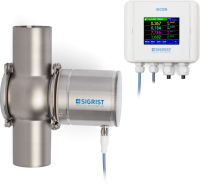

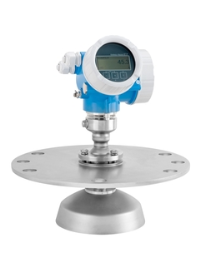

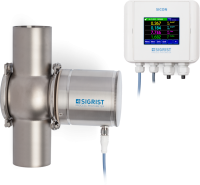

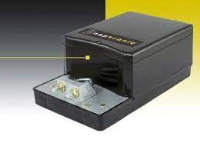

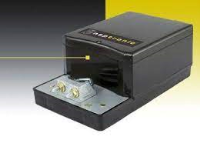

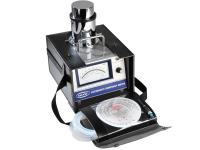

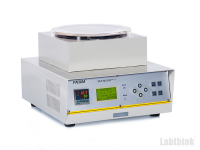

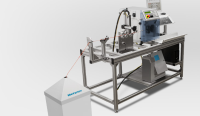

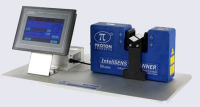

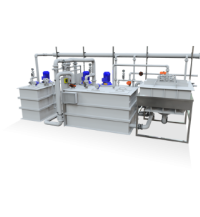

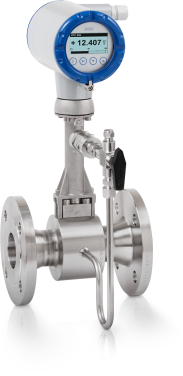

C230M Oxygen Transmission Rate Test System is designed and manufactured based on the coulometric sensor method (aka. equal pressure method) and conforms to ASTM D3985, ASTM F2622 and ISO 15105-2. This instrument can be used to measure the oxygen transmission rate of barrier materials with high, and medium barrier properties with high accuracy and high efficiency. The instrument features Labthink’s patented design of integrated test block consisting of three permeation cells. Equipped with a high precision coulometric sensor and Labthink’s professional computer-controlled system, the instrument can regulate and control the temperature, humidity and flow rate precisely, guaranteeing high sensitivity and excellent repeatability of test results. C230M is applicable to the determination of oxygen permeability of plastic films, sheeting, paper, and other packaging materials used in food, pharmaceutical, medical apparatus, consumer products, photovoltaic and electronic industries, etc. Optional accessories extend the capability to testing complete packages and systems such as bottles, pouches, cartons, blister packs, tubes and more.

High Precision

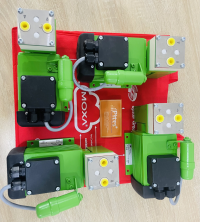

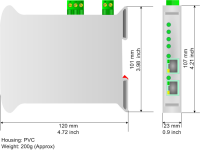

- Patented integrated test block with advanced hydrodynamic and thermodynamic designs.

- Labthink’s proprietary thermostat technology ensures that the test block is precisely temperature controlled and remains stable throughout the test.

- Temperature and humidity sensor for independent monitoring of test cells.

High Efficiency

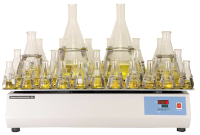

- Three identical specimens can be tested simultaneously, which meets the requirements for parallel test.

- Three distinct specimens can be tested under the same testing condition, delivering higher throughput while reducing the number of instruments required.

Labor Saving

- Automatic temperature and humidity control eliminate the need for operator monitoring and adjustment.

- Automatic flow rate control ensures constant flow during the testing process and minimizes any errors caused by an unstable flow rate.

- No need to verify the system using different reference film for different testing range.

Simplified Operation

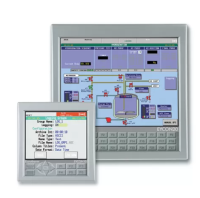

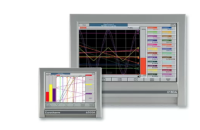

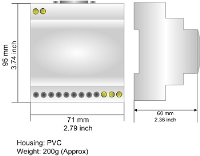

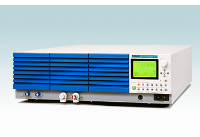

- 12’’ touch-screen pad powered by WindowsTM 10 operating system

- Fast automatic testing process

- Optional DataShieldTM software and accessories for automatic data management

Product Features

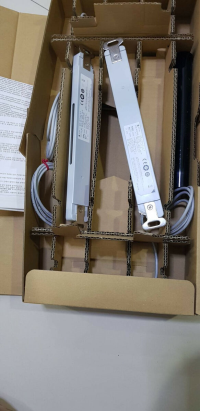

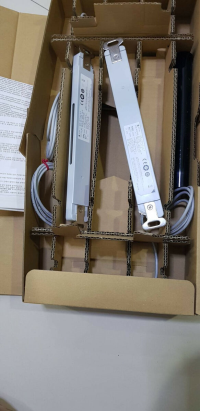

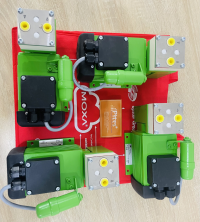

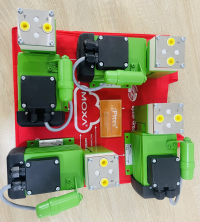

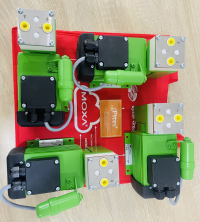

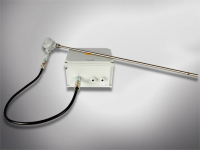

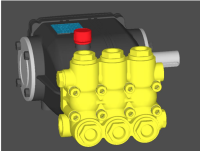

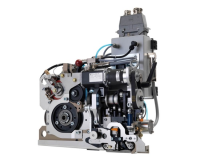

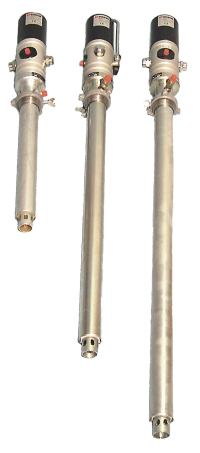

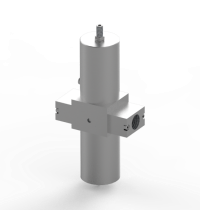

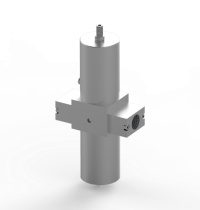

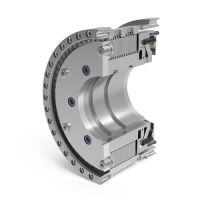

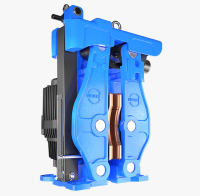

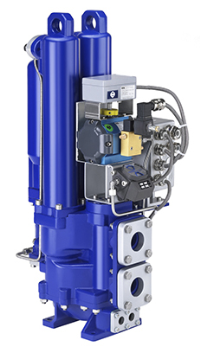

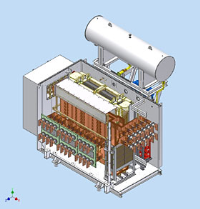

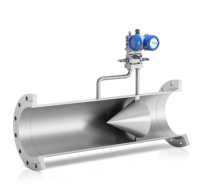

New Generation Integrated Testing Block

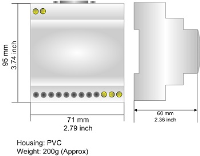

The patented three-cell integrated test block structure using advanced thermodynamics and hydrodynamics analysis greatly improves the temperature, humidity and flow measurement accuracy across the three test cells and supports simultaneous testing of three samples.

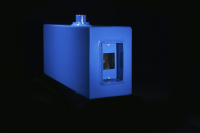

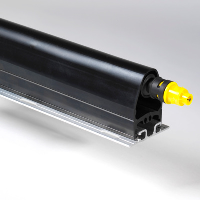

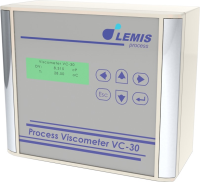

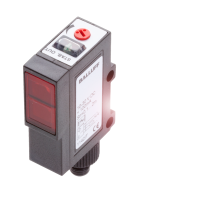

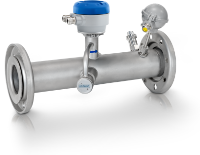

Automatic Control of Temperature, Humidity and Flow Rate

The internal temperature and humidity of the instrument are automatically adjusted with temperature and humidity sensors, maintaining the stability of the test specimen environment.

Automatic flow rate control ensures constant flow during the testing process and minimizes any errors caused by an unstable flow rate.

Easy-to-use and High-efficiency System

The automatic test mode, combined with the instrument features, eliminates the need for manual adjustments to quickly obtain accurate results, saving training costs and releasing staff from manual monitoring so that they are available for other tasks.

The professional test mode provides flexible and rich instrument control functions to meet individual scientific research needs.

Unique, optional, DataShieldTM system, meets the requirements for centralized management of user data. It supports a variety of formats of exported data. Reliable security algorithms are used to prevent data leakage. It supports universal wired and wireless LAN, optional private wireless network and third-party software.

User-oriented Service Concept

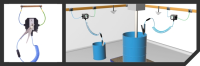

Adhering to our user-oriented service concept, Labthink has created a customization system that provides flexible and comprehensive customization services for the accommodation of non-standard specimens and packages.

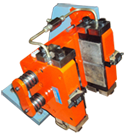

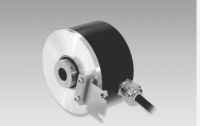

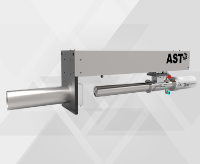

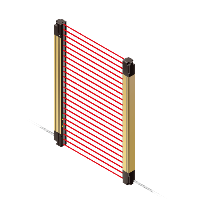

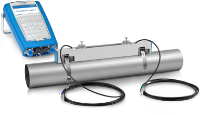

Test Principle

The pre-conditioned specimen is mounted between the upper and lower chambers at ambient atmospheric pressure. The upper chamber contains oxygen or air and the lower chamber is slowly purged by a stream of nitrogen. Due to the concentration difference between the two chambers, oxygen molecules permeate through the specimen into the nitrogen side and are taken to the coulometric sensor where proportional electrical signals are generated. The oxygen transmission rate is then obtained by analyzing the signals and calculating the volume of oxygen measured by the sensor. For whole package samples, high purity nitrogen flows inside the package, and oxygen or air flows outside.

Test Standards

ISO 15105-2, ASTM D3985, ASTM F2622, ASTM F1307, ASTM F1927, DIN 53380-3, GB/T 19789, GB/T 31354, JIS K7126-B and YBB 00082003-2015